Innovative Planning for Fastening Solutions

Precision. Efficiency. Excellence.

Our seamless assembly planning is the key to unlocking unparalleled efficiency, precision, and quality in your fastening processes. Discover how our expertise in assembly planning can elevate your fastening solutions to new heights.

.jpg)

Optimizing

Assembly Planning

The planning advantage.

Our integrated solutions streamline fastening processes, reducing production time and increasing overall efficiency.

Careful planning helps identify potential issues and bottlenecks in the assembly process, reducing errors and the need for rework.

Planning ensures that fastening processes are executed with precision, resulting in higher product quality and fewer defects.

Efficient assembly planning leads to cost savings by minimizing material waste and reducing labor and operational costs.

Well-planned assembly processes lead to shorter lead times, improving delivery schedules and customer satisfaction.

Consultation and Assessment

Our journey begins with a thorough consultation, where we gain a deep understanding of your specific needs and challenges. We assess your current fastening processes to identify areas for improvement.

Customized Solution Design

Based on the assessment, our experts craft a tailored integration plan. We design a solution that aligns with your goals, industry standards, and quality requirements.

Product Sourcing

We source the finest fasteners and tools, ensuring they meet the highest quality standards. Our network of trusted suppliers guarantees reliable and high-performance products

Integration Implementation

Our experienced team takes charge of the integration process, implementing the custom-designed solution seamlessly into your operations. We minimize disruptions and ensure a smooth transition.

Quality Assurance

Throughout the integration process, we maintain stringent quality control measures. Our commitment to excellence guarantees that your fastening processes meet the highest industry standards.

Testing and Validation

We conduct rigorous testing and validation to ensure the integrated solution performs optimally. This step guarantees reliability and efficiency in your fastening operations

Consultation and Assessment

Our journey begins with a thorough consultation, where we gain a deep understanding of your specific needs and challenges. We assess your current fastening processes to identify areas for improvement.

Consultation and Assessment

Our journey begins with a thorough consultation, where we gain a deep understanding of your specific needs and challenges. We assess your current fastening processes to identify areas for improvement.

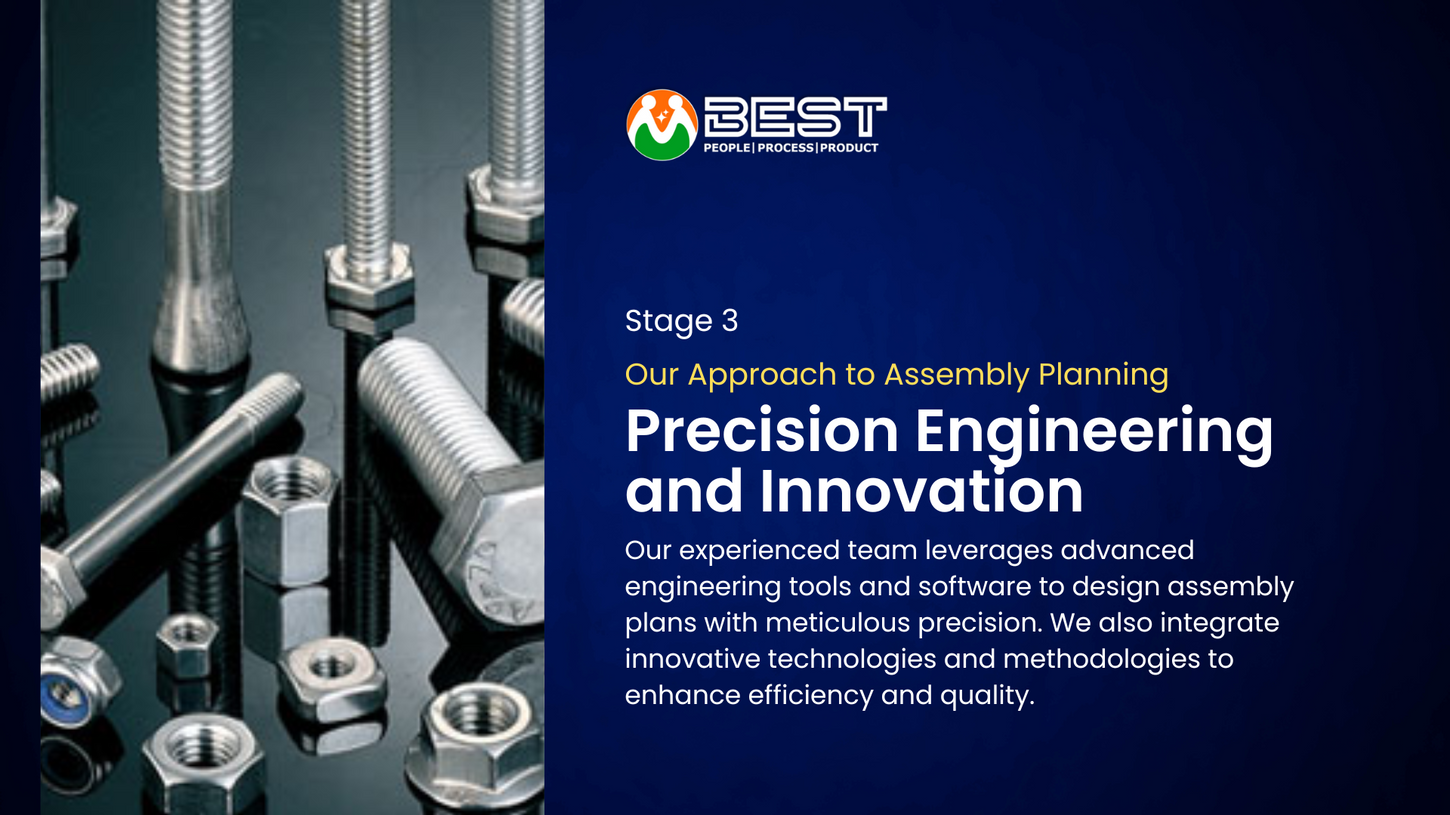

Our Approach to Assembly Planning

Collaborate with BEST Fastening Solutions for a revolutionary Assembly Planning experience that streamlines and enhances your operational efficiency.

Consultation and Assessment

Our journey begins with a thorough consultation, where we gain a deep understanding of your specific needs and challenges. We assess your current fastening processes to identify areas for improvement.

Customized Solution Design

Based on the assessment, our experts craft a tailored integration plan. We design a solution that aligns with your goals, industry standards, and quality requirements.

Product Sourcing

We source the finest fasteners and tools, ensuring they meet the highest quality standards. Our network of trusted suppliers guarantees reliable and high-performance products

Integration Implementation

Our experienced team takes charge of the integration process, implementing the custom-designed solution seamlessly into your operations. We minimize disruptions and ensure a smooth transition.

Quality Assurance

Throughout the integration process, we maintain stringent quality control measures. Our commitment to excellence guarantees that your fastening processes meet the highest industry standards.

Testing and Validation

We conduct rigorous testing and validation to ensure the integrated solution performs optimally. This step guarantees reliability and efficiency in your fastening operations

Consultation and Assessment

Our journey begins with a thorough consultation, where we gain a deep understanding of your specific needs and challenges. We assess your current fastening processes to identify areas for improvement.

Consultation and Assessment

Our journey begins with a thorough consultation, where we gain a deep understanding of your specific needs and challenges. We assess your current fastening processes to identify areas for improvement.

.jpg)

Our Approach to Assembly Planning

Stage 1

Assessment and Analysis

We begin by conducting a thorough assessment of your fastening needs. This includes an in-depth analysis of materials, industry standards, and production requirements. This initial step forms the foundation of our assembly planning process

Benefits

Holistic Understanding of Assembly Needs

Efficiency Gaps Identification

Resource Optimization

Risk Mitigation Strategies

Data-Driven Decision-Making

FAQS

An assembly planning approach is crucial for optimizing workflows, reducing costs, and ensuring the efficient integration of components. It allows for the systematic organization of tasks, leading to enhanced productivity and overall project success.

Our assessment phase is designed to provide a comprehensive understanding of project needs, identify inefficiencies, and strategize for optimal resource utilization. This critical step sets the foundation for a well-informed and effective assembly planning process.

Our precision engineering involves meticulous design, stringent quality control, and the integration of advanced technologies. This approach ensures that the assembly processes are accurate, reliable, and aligned with the highest industry standards.

Continuous improvement is integral to refining assembly processes over time. By gathering feedback, monitoring performance, and embracing emerging technologies, we ensure that your assembly processes stay efficient, adaptable, and at the forefront of industry advancements.

Yes, our planning approach is designed to be adaptable. We understand that project requirements may evolve, and we are equipped to incorporate changes seamlessly into the planning process. Open communication and flexibility are key elements of our service.

Consultation and Assessment

Our journey begins with a thorough consultation, where we gain a deep understanding of your specific needs and challenges. We assess your current fastening processes to identify areas for improvement.

Customized Solution Design

Based on the assessment, our experts craft a tailored integration plan. We design a solution that aligns with your goals, industry standards, and quality requirements.

Product Sourcing

We source the finest fasteners and tools, ensuring they meet the highest quality standards. Our network of trusted suppliers guarantees reliable and high-performance products

Integration Implementation

Our experienced team takes charge of the integration process, implementing the custom-designed solution seamlessly into your operations. We minimize disruptions and ensure a smooth transition.

Quality Assurance

Throughout the integration process, we maintain stringent quality control measures. Our commitment to excellence guarantees that your fastening processes meet the highest industry standards.

Testing and Validation

We conduct rigorous testing and validation to ensure the integrated solution performs optimally. This step guarantees reliability and efficiency in your fastening operations

Consultation and Assessment

Our journey begins with a thorough consultation, where we gain a deep understanding of your specific needs and challenges. We assess your current fastening processes to identify areas for improvement.

Consultation and Assessment

Our journey begins with a thorough consultation, where we gain a deep understanding of your specific needs and challenges. We assess your current fastening processes to identify areas for improvement.

Our Approach to Assembly Planning

Partner with BEST Fastening Solutions for a transformational Assembly Planning journey that optimizes your operations.

Why Request a Consultation with BEST?

Take the first step toward optimization by requesting a consultation with our experts. We're here to understand your unique needs, answer your questions, and provide tailored guidance.

Our consultations are designed to uncover your specific challenges and objectives, enabling us to propose a custom integration plan that suits your requirements.

Benefit from the knowledge and expertise of our seasoned professionals who specialize in fastening integration across industries

We'll assess your current fastening processes and identify areas where integration can enhance efficiency, quality, and cost-effectiveness.

Discover how our seamless integration approach can minimize downtime, reduce waste, and optimize overall production.

Learn how our rigorous quality control measures ensure that your fastening operations consistently meet industry standards.

Expert Advice

To request a consultation, simply fill out the form with your contact information and any specific questions or requirements you have. Our team will promptly reach out to schedule a consultation at your convenience.

.jpg)

.jpg)